Products

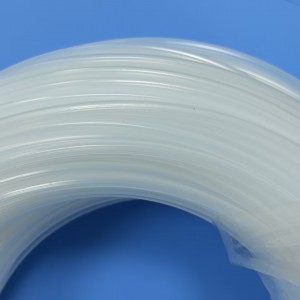

Bare Fiber Optic Protection Tube with 4.6×2.5mm

Stock Sample is Free & Available

Acceptance: OEM/ODM

Detail Information

|

Name |

Bare Fiber Optic Protection Tube with 4.6x2.5mm |

|

Spec. |

4.6*2.5 |

| Use | FTTx&FTTH |

| Material | EVA |

| Shape | Rectangle |

| Color | Clear |

Benefits

This high quality beer line will keep your previous beverage in it's best possible condition in the process.

Easy to use. Tubing quickly attaches to these fittings.without the aid of a tool. Quick remove of the tubing for cleaning. Tubing seats very tightly and will not leak! Guarantee quality and ensure a solid connection with your keg post.

The female screw part screws onto a threaded disconnect and 5/16'' beer line pushes into the other end. The beerline is securely locked in but can easily be removed if necessary.

Description

Optical fiber protection tube, also known as bare fiber protection tube, and transparent bare fiber protection tube. It is made up of low density polyethylence.Can be widely used for fiber optic transfer box, optical distribution frame, protection of the optical bare fiber in the light transfer box and the fiber optic after peeled. It is can effectively avoid damage and fold of fiber optic.

The bare fiber protection pipe is mainly used for the protection of the bare fiber segment in the distribution frame, the optical fiber splicing box and the fiber core after the bare fiber is stripped, which can effectively protect the bare fiber fiber from damage. Good protection, not easy to break.

Features

1. Does not affect the optical conductivity of the fiber;

2. Protect the connection point and improve the mechanical strength;

3. Simple operation, reducing the risk of damage to the fiber during installation;

4. Transparent casing, which shows the status of the fiber connection at a glance;

5. Fast shrinkage and high construction efficiency;

6. High working temperature and wide range of use;

7. Sealing structure makes the connection have good temperature and humidity resistance