Products

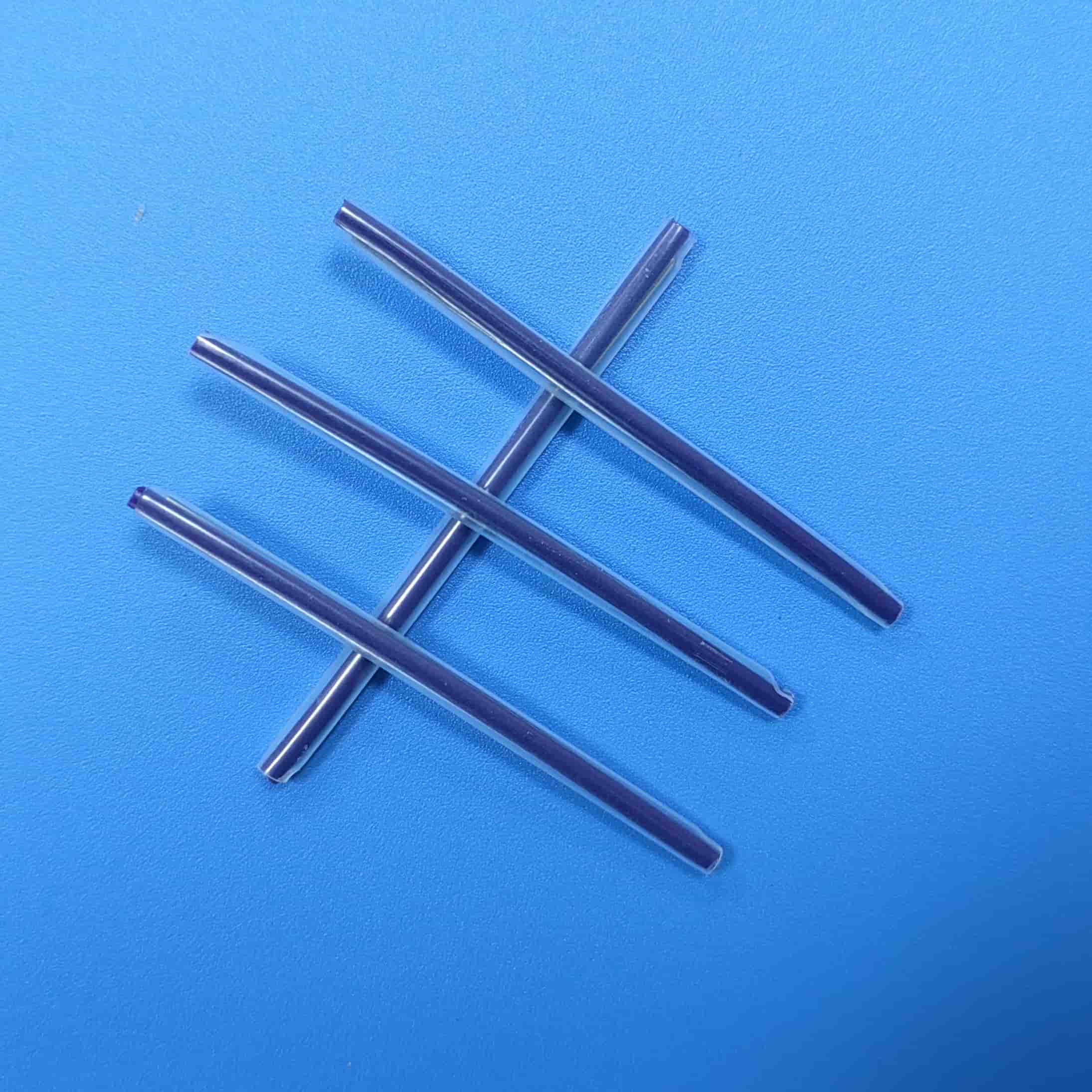

Fiber Optic Splice Sleeve in Purple with 304SS

Stock Sample is Free & Available

Acceptance: OEM/ODM

Detail Information

|

Name |

Fiber Optic Splice Sleeve in Purple with 304SS |

|

Spec. |

1.2*60*304 |

| Use | FTTx&FTTH |

| Material | EVA |

| Length | 60mm |

| Color | Purple |

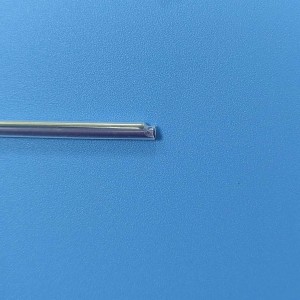

| OD After Shrink | 1.4mm |

| Use For | Fiber Distribution Box |

The following factors should be carefully considered when choosing the right heat shrink tubing:determine the inner diameter, shrinkage and length of the covered object, the size of the object to be wrapped. Determine the appropriate wall thickness according to the application scenario and environment. The material, characteristics, operating temperature and shrinkage temperature of the heat shrink tube determine the overall compatibility of the application field.

Electric Features

1.Continue operating Temperature:-45°C~125°C;

2.Shrink Temperature :Start at 70°C;full recovery at 125°C;

3.Inner layer glue melt temperature:70°C~100°C;

4.Shrinking ratio:2:1,3:1, 4:1

5.Waterproof , RoHS compliant, outer layer Flame-retardant.

6.Standard color: Transparent (Other color available upon request.)

7. Stock type: 1.2mm 60mm 100pcs/bag type

Application of Heat Shrink Tube

The heat shrink tube is for insulation and protection of components, terminals, wiring connectors and wiring strapping, marking and identification mechanical protection. The outer tube is a transparent heat shrinkable sleeve, which has the performance of insulation and flame retardant, corrosion and wear resistance, and can clearly view the optical fiber welding situation at any time when welding optical fiber.

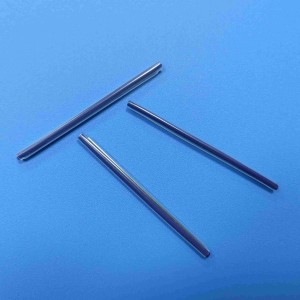

Description

Stock lengths are 60mm, but are also available in 50mm or 45mm length for smaller packaging requirements. This product is constructed with an inner EVA melt-able adhesive tube, a polyolefin heat-shrink outer tube and either single or dual strength member. Our single strength member sleeve which has become an industry standard, utilizes a stainless-steel member. Our dual strength member sleeve is designed to “sandwich” the drop cable, thus eliminating any undue stress on the fiber. The tubes are clear to allow viewing the color of the fiber after splicing. The entire assembly is heat bonded to ensure that all members maintain perfect alignment during shipping, handling, and shrinking.