Products

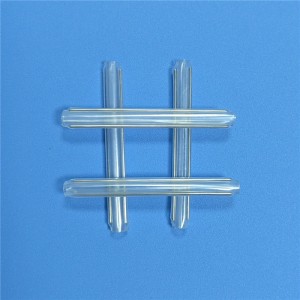

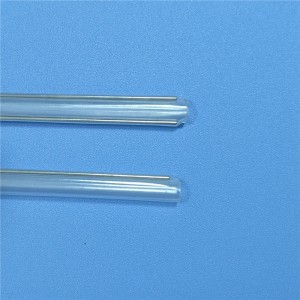

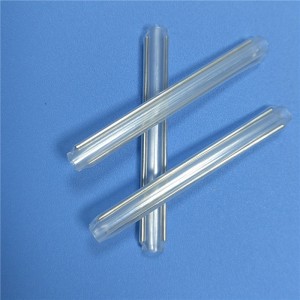

Fusion Heat Shrinkable Protection Tube with Double 304 Stainless Steels

Stock Sample is Free & Available

Acceptance: OEM/ODM

Detail Information

| Name | Fusion Heat Shrinkable Protection Tube with Double 304 Stainless Steels |

| Spec. | 1.2*60*304 |

| Use | FTTx&FTTH |

| Material | EVA |

| Length | 60mm |

| Color | Clear |

| Steel Rod Number | 2 |

| Use For | Fiber Distribution Box |

Description

This product is composed of transparent heat shrinkable sleeve (outer tube, transparent hot melt tube (inner tube and reinforced stainless steel rod (stiffener), which is specially used for FTTH fiber-to-the-home engineering operations and is a protective element designed for outdoor leather fiber optic cable welding. By hot welding, all the leather cables or between the leather fiber cables and the single-core jumper can be welded in the sleeve.

Optic Fiber Protective Sleeve is applied to protection fiber optical splice. It is made up of stainless reinforcing steel rod, heat shrinkable tubing and cross linked polyolefin. Rebuild the covering layer of the fiber and provide excellent mechanical strength in the joint. Guarantee good optical transmission performance. Easily operating to the optical fiber during installation without damaging and clear sleeve make it easy to detect splice before shrinkage.

Features

1.Single holed (preshrunk) ends eliminates improper fiber threading;

2.Smooth, deburred stainless steel reinforcing member ends decrease the risk of fiber damage during installation;

3.Extended liner length prevents contact between the fiber and the backbone;

4.Clear sleeve design persign permits easy centering of splice before heating;

5.Sealing structure makes the splice free from effect of temperature and humidity from environment;

6.Operating temperature:-45 ℃to +100℃;

7.Minimum fully recovery temperature:120℃.

Application

1. Use the enhanced wire, hot-melt tube and cross-linked polylefin composition;

2. Reconstruct the fiber coating;

3. Junction to provide a good mechanical strength;

4. Ensure good optical transmission properties.