Products

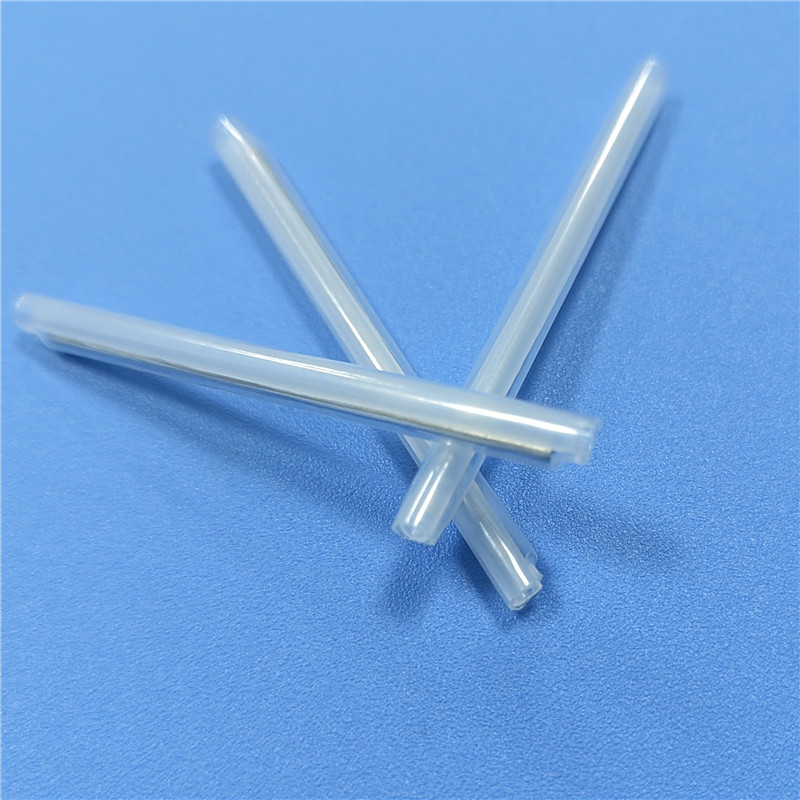

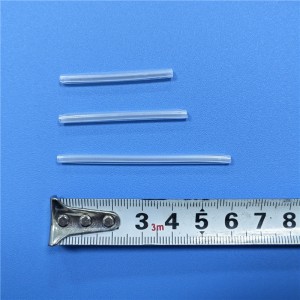

Optical Fiber Heat Shrink Protective Tube in 3.5mm Diameter 45mm Length

Stock Sample is Free & Available

Acceptance: OEM/ODM

Detail Information

| Name | Optical Fiber Heat Shrink Protective Tube in 3.5mm Diameter 45mm Length |

| Spec. | 1.2*45*304 |

| Use | FTTx&FTTH |

| Material | EVA |

| Length | 45mm |

| Color | Clear |

Description

Fiber optic heat shrink tubing is a material that is able to protect or connect optical fibers by heat shrinkage. It is constructed of polyolefin or epoxy resin and has a hot melt adhesive. Its role is to apply pressure to the optical fiber, so as to avoid the influence of bending, twisting and stretching of the optical fiber during use, and at the same time reduce the influence of external noise.

Applications

It consists of heat shrinkable polyolefin, hotmelt adhesive and a rod of reinforcing the splice.

To rebuild the coating of fiber to provide mechanical strength at the fusion joint area and keep optical trnsmission properties.

Product Details

Superior Quality: Sleeves shrink tightly to exclude air and hold the rod firmly preventing abrasion of delicate glass fibers;

Attractive Outlook: SUS304 steel rod plays a good fix position in the middle of sleeve. The cutting edges are neat and beautiful;

Ideal Transparency: Transparent casing for a clear vie of the fiber connection status.

The transparent outer layer is convenient to detect whether the fiber joint is connected correctly, so that the fiber can be assembled simply and safely, and the optical transmission characteristics of the fiber can be maintained after shrinkage, providing strength and protection for the fiber joint. It can avoid damage to the optical fiber during installation. Protect the spliced optical fiber, and the reinforcement inside makes the contact more firm. After the completion of optical fiber splicing, it plays the role of sheath, the purpose is waterproof, dustproof, anti-decay!

Operation Steps

1.Strip fiber jacket and bare fiber

2.Fiber through heat shrinkable tube

3.Cut fiber with a light cutter

4.Dissolved Optical Fiber

5.Heating Process

6.Finished